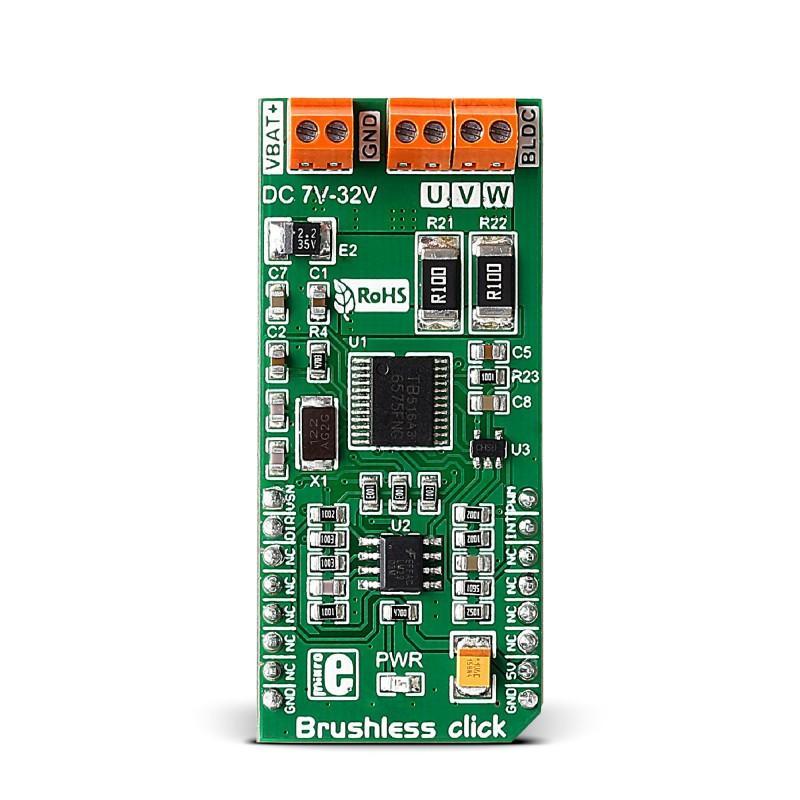

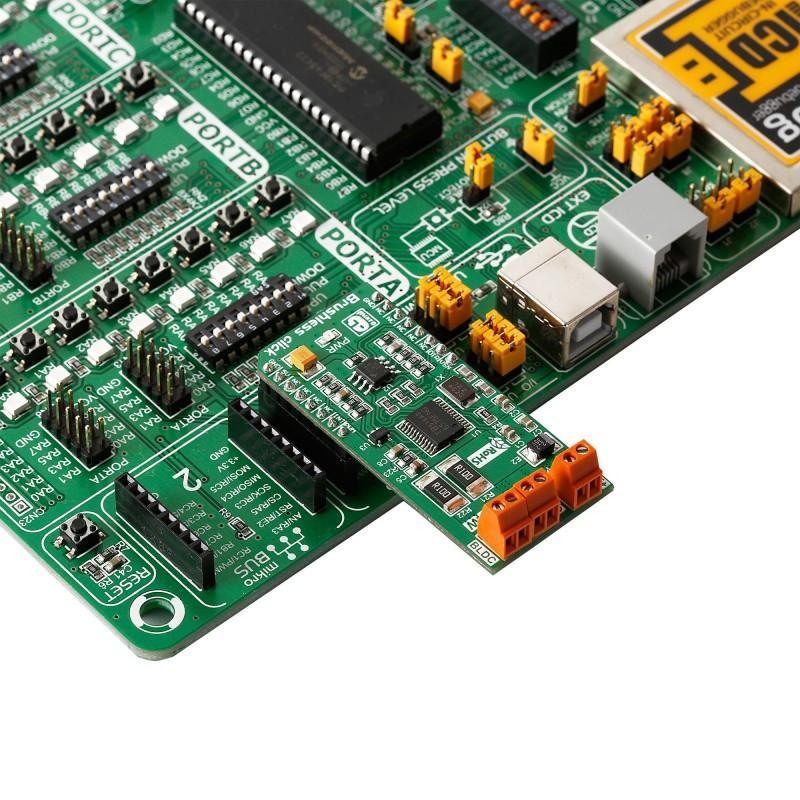

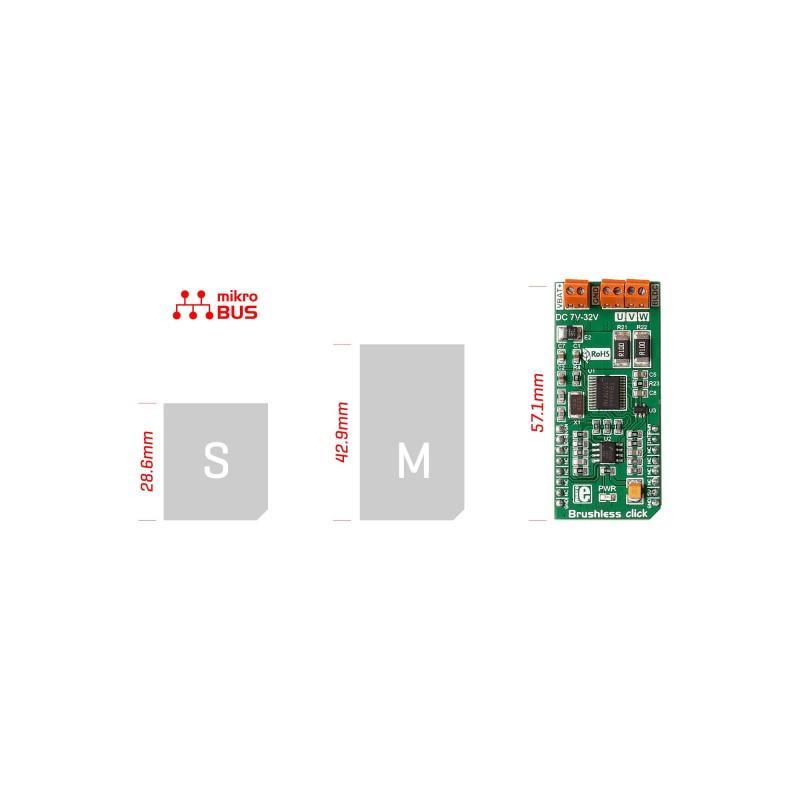

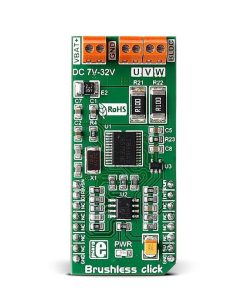

Brushless click – MikroElektronika 3-Phase Full-Wave Brushless DC Motor Driver

Brushless click carries Toshiba’s TB6575FNG IC for driving 3-phase full-wave Brushless DC motors — which are ideal for powering flying drones. The click is able to safely drive external motors with up to 32V/2A.

The board features three pairs of on-board screw terminals. VBAT is for connecting an external 7-32V DC power supply. The other two are for connecting an external motor.