Industrial MODBUS RS485 Hydrogen Sulfide H2S Sensor Seeed Studio

$ 279,00 $ 111,60

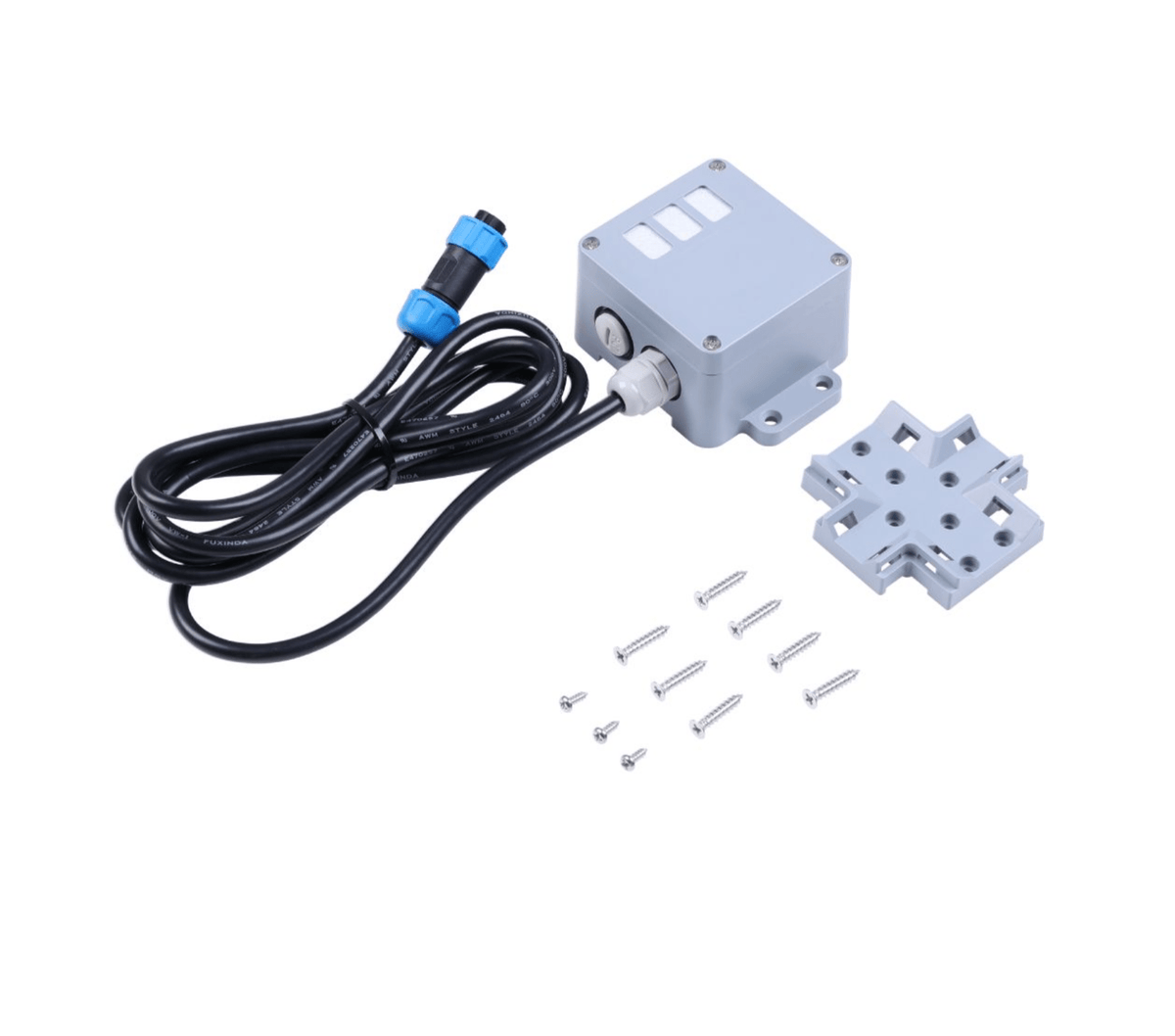

Industrial MODBUS RS485 Hydrogen sulfide H2S Sensor Waterproof Connector

Hydrogen sulfide is the most common source of where the stinky smell came from in our daily life and it has a tremendous effect on our healthy life. Different levels of hydrogen sulfide make a different impact, for example, a small number of hydrogen sulfide only make you suffer from a bad smell. However, when one area concentrates a big amount of large hydrogen sulfide, it will hurt your olfactory system and poisoning will happen.

There are different kinds of methods of producing hydrogen sulfide whether by humans or by nature. The excretion produced by the livestock farming industry, in the process or reserve excretion by livestock and recycling of the excretion will produce an enormous amount of ammonia gas. Heavy industry using energy also producing a lot of hydrogen sulfide, because the process of burning coal, fuel, and natural gases for making energy also producing a huge amount of hydrogen sulfide and faces the risk of improperly disposing of hydrogen sulfide.

RS485 H2S Sensor S-H2S-01adopted import sensor chip from Germany with the ability to monitor hydrogen sulfide concentration, air temperature, and humidity at the same time. The sensor transmits data with the help of the RS485 Modbus RTU protocol. The sensor contains excellent features as it can respond to gas or environment with high speed and sensibility, has the ability to tolerate disturbance, adopts compensation algorithm and adjustable standards, all of that to assure the accuracy of the sensor. This equipment was powered by 5V DC, able to support most of the sensors in the market. Equipment can be easily integrated into most of the system without a complex setup procedure.

Solid polymer electrochemical technology is a revolutionary innovation in the field of electrochemical detection. This technology is based on the principle of electrochemical catalytic reaction triggered by different target gas leading to sending out a different electrical signal that is directly proportional to the gas concentration. The sensor module is composed of three catalytic electrodes, a solid electrolyte, and gas diffusion holes. The gas reaches the working electrode of the sensor through the diffusion holes, an electrochemical redox reaction occurs on the porous micro-surface of the electrode, the solid electrolyte conducts electron transfer, and generates a current signal as an output. The current signal can characterize the gas concentration.

Features

- Multiple Uses: Ability to monitor hydrogen sulfide concentration, air temperature, and humidity.

- Highly resist of Disturbance: Toleration for extreme temperature and exposure to high levels of ammonia gas.

- Application for a variety of areas: Livestock farming, gas leaking detection for heavy industry and atmospheric environmental gas detection, etc.

- Customer-friendly: Easy to set up and support adjustment for different uses.

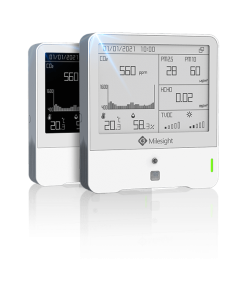

Sensor Hub Data Logger is an easy-to-deploy 4G cellular station. It uses the MODBUS-RTU RS485 protocol to communicate with sensors and can collect various sensor data simultaneously. Sensor Hub consists of 4 RS485 data channels. With extension hubs / RS485 splitters, it can connect with a maximum of 32 sensors at one time. The data is collected and sent to the cloud (either to the SenseCAP server or the client’s private server) via 4G/3G/2G (as shown below).

Designed with industry standards and IP66 rated, Sensor Hub is suitable for outdoor and harsh environments, resistant to UV, rain, and dust, etc. GNSS is embedded for location tracking.

Sensor Hub is also equipped with 10MB onboard memory, to store more than 700,000 measurements locally in case of a bad connection.

Applications

- Livestock farming (pig houses, chicken coops, cattle herding, etc.)

- Smart public toilet ammonia and odor monitoring

- Ammonia monitoring in landfills and sewage treatment plants

- Gas leak detection for heavy industry

- Atmospheric environmental gas detection

- Other sensor applications

Specification

|

The basic parameters |

||||||

|

Product model |

S-H2S-01 |

|||||

|

Supply Voltage |

4.5 ~ 5.5V DC (recommended 5V power supply). |

|||||

|

Supported Protocol |

MODBUS-RTU RS485 |

|||||

|

IP Rating |

IP65 (The equipment should be protected from direct sunlight and rain over long periods of time). |

|||||

|

Operating Temperature |

-40°C to 50°C (best operating temperature 20 to 35 °C). |

|||||

|

Operating Humidity |

15 to 95% RH (non-condensation) (best operating humidity 50%RH). |

|||||

|

Ambient Pressure |

Atmospheric pressure ±10%. |

|||||

|

Cable Length |

2 meters |

|||||

|

Measurement Parameters |

||||||

|

|

Measurement |

Measurement accuracy |

Resolution |

|||

|

Ammonia |

0~100 ppm |

± 5% F.S |

0.1 ppm |

|||

|

Temperature |

-40~50 °C |

± 0.5 °C |

0.1 °C |

|||

|

Humidity |

10~95 %RH |

± 5% |

0.1 %RH |

|||

|

Power |

||||||

|

Operating Current |

6mA(Max,5V DC)

|

|||||

|

Performance reference |

||||||

|

|

Parameter |

Min |

Typical value |

Max |

Unit |

|

|

RS-485 mode |

Warm-up Time [1] |

— |

5[2] |

— |

minutes |

|

|

Poll Rate [3] |

— |

1 |

— |

seconds |

||

|

Response time[4] |

— |

30 |

— |

seconds |

||

[1] The time from when the sensor is powered on to when the data is read. Note the parameter when the sensor is powered on.

[2] If started in an environment with clean air it requires less time

[3] The measurement data update interval, after the power-up warm-up time, if the power supply continues, the sensor periodically updates the reading at this interval.

[4] T90<30s

Part list

| 1 | Sensor | 1 |

| 2 | Cap | 4 |

| 3 | Fiaxation equipment | 2 |

| 4 | Self-drilling Screw | 4 |

Documentations

H2S Sensor Datasheet

Fast Shipping and Professional Packing

Through our long-term relationship in a long-standing partnership with UPS, FedEx, DHL and many other top global carriers we can provide a variety of shipping options. Our warehouse employees will pack every item to our exacting specifications. The goods you send us are checked thoroughly and secured properly prior to shipping. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the world is clear. Both Europe as well as the USA have warehouses and distribution centres.

Orders that contain more than one item are assigned processing times in accordance with the item.

We will inspect each and every one of the items ordered before shipping. Today, most orders will be shipped within 48 hours. The delivery time should be between 3-7 days.

Returns

The stock market is always changing. It's not entirely managed by us, since we have multiple organizations, such as the factory and our storage. Stock levels can fluctuate at any given time. Please understand it may happen that your order will be out of stock after the order is placed.

The policy is for 30 days. If you have passed 30 days in the past since you purchased, unfortunately we can't offer you a refund or exchange.

To be eligible for a refund, your item must be in good condition and in the same state that you received it. The item must be in the original packaging.

Related products

Gas Sensor